Kuma Stove Efficiencies

| Kuma Wood stoves | HHV Efficiency | LHV Efficiency | Tax Credit Qualified? |

|---|---|---|---|

| Aspen LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Tamarack LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Aberdeen LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Ashwood LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Wood Classic LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Cambridge LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Alpine LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Cascade LE-1 | 78% | 84% | YES, if installed before 01/01/2026 |

| Applewood Cook Stove | N/A | N/A | NO |

Why efficiency is so important.

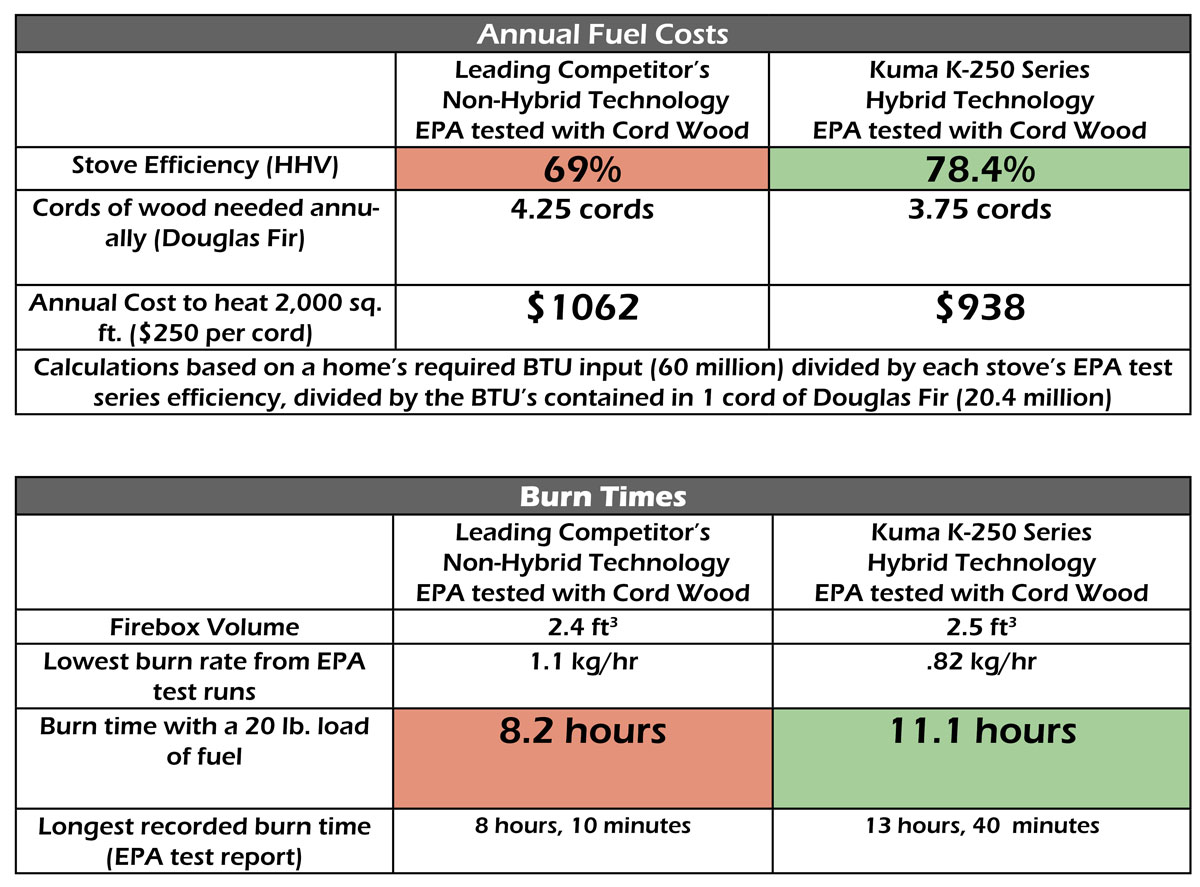

Over the life of a stove (let's say 15 years for example) Investing in Kuma's efficient Hybrid Technology would save you nearly $2,000 in fuel costs, which is equal to 23,000 lbs of wood that you do not need to chop, stack and haul into the house. So if you like to crunch numbers, you can compare the fuel costs and burn time comparison below. We compared our new hybrid technology to a leading Canadian manufacturer's non-hybrid technology. All of the data is taken from official EPA test reports:

Hot fires always burn cleaner... or do they?

The easiest way to clean up a wood fire is to burn it hot, so many manufacturer's use thermal combustion (hot secondary combustion) to make their stoves burn clean. The problem is, as you can see in the chart above, is that a hot fire is not a long burning fire. 20 years ago when emissions standards were not as strict, you could acheive a decent overnight burn and still be relatively clean. With 2020 emissions standards many stoves are now lacking adequate low burn rates. Kuma's Hybrid technology uses thermal combustion combined with a combustor that actually lowers the temperature at which wood smoke burns! Because of this our stove burned for over 5 hours longer than our competitor's stove during it's emission testing.

What is HHV and LHV, and what is the difference?

Both HHV and LHV are references to the Heating Value of a particular fuel, specifically firewood in the case of wood stoves. They are abbreviations for "Higher Heating Value" and "Lower Heating Value". The Higher Heating Value regards all of the BTU's in the wood as usable input into the stove, while the Lower Heating Value only regards most of the BTU's in the wood as usable input into the stove. All is higher than most, thus the higher value, and most is lower than all, thus the lower value. Why does the LHV only regard most of the BTU's as input? It has everything to do with moisture in the wood, and the evaporation of that moisture during combustion. Evaporating the moisture requires some of the BTU's from the wood. Here's a simple equation that illustrates the relationship between HHV and LHV...

All of the BTU's (HHV) - Some of the BTU's (used for moisture evaporation) = Most of the BTU's (LHV)

So, how does this affect wood stove efficiencies? It's simple mathematics, BTU's out divided by BTU's in. The dividend (BTU's out) is the same in both HHV and LHV calculations. It's the divisor that changes, a lower number for LHV, or the higher number for HHV. A lower divisor (LHV) will always produce a higher quotient (in this case, efficiency %).

If you have additional questions about HHV and LHV, and their differences, call us at 888-714-5294. We'll be glad to help explain it further.

Why do we show both HHV and LHV efficiency numbers?

The issue of efficiency can be somewhat confusing if you're not sure which numbers are being used. If one stove manufacturer publishes only HHV numbers, and another manufacturer publishes only LHV, a direct comparison of efficiency cannot be made. Most manufacturers only publish LHV efficiencies since they are higher and that looks better than being lower. We publish our LHV efficiencies to help you make a direct comparison to other stoves. The IRS did allow the use of LHV for the purpose of qualifying for the 25C tax credit ($300 credit that expired in 2020). For the 25D tax credit (in effect through 2023) the IRS has mandated the use of HHV efficiency (75% or better). We publish our HHV efficiencies because HHV is used by the US EPA as the "actual" efficieny on its certified stove list, and because virtually all other heating equipment in North America is rated using HHV. In order to compare the efficiency of a Kuma stove to that of your furnace, for example, you need the HHV efficiency number.

New EPA Standards All Kuma Stove models are certified under the current new standards

The EPA's New Source Performance Standards (NSPS) is the program that regulates emissions for wood burning appliances. The original NSPS was initiated in 1988, and the more common "Phase II" took effect on July 1st, 1990. A Phase II certified stove with a catalytic could produce no more than 4.5 grams/hr of pollution, and a Phase II certified stove without a catalytic could produce no more than 7.5 grams/hr of pollution. Now, 25 years later, the EPA has finally updated their NSPS to reflect advancements in technology. The new EPA regulations on wood burning appliances took effect on May 15, 2015, and is being implemented in two phases over the next 5 years. As of May 15, 2015, all regulated wood burning appliances manufactured in, or imported to, the United States, must produce no more than 4.5 grams/hr of pollution. In the new standards, there is no difference between a stove with a catalytic and one without. In May of 2020, all regulated wood burning appliances will be required to produce no more than 2.5 grams/hr of pollution.

2020 EPA Test Reports

K-250 Series (Edition 6 - Ashwood LE, Wood Classic LE, Cambridge LE, Cascade LE).

K-250 Series (Catalyst Equivalency Edition 4 - Ashwood LE, Wood Classic LE, Cambridge LE, Cascade LE)

K-180 Series (Edition 4 - Aspen LE, Tamarack LE, Aberdeen LE, Alpine LE).

K-180 Series (Catalyst Equivalency Edition 4 - Aspen LE, Tamarack LE, Aberdeen LE, Alpine LE).

2024 EPA Test Reports

K-181 Series (Aspen LE-1, Tamarack LE-1, Aberdeen LE-1, Alpine LE-1)

K-251 Series (Ashwood LE-1, Wood Classic LE-1, Cambridge LE-1, Cascade LE-1)

Frequently Asked Questions about Hybrid Technology

Q: What is a catalytic combustor?

A: A combustor is a device that lowers the temperature at which wood smoke burns. This converts smoke and unwanted pollution into useable energy for your home, especially during low burn rates. Combustors are now being combined with non-catalytic technology (burn tubes) to create ultra-efficient hybrid wood stoves.

Q: Do they burn cleaner than non-catalytic stoves?

A: Yes, Yes, Yes and No. In virtually all burn rates, a catalytic or hybrid stove provides a cleaner burn than non-catalytic stoves:

|

Burn Rate: |

Low |

Medium |

Medium High |

High |

|

Emissions from a Kuma K-180 Series Hybrid Stove |

.38 gph |

.39 gph |

.40 |

2.03 |

|

Emissions from a leading Canadian Non-Hybrid Stove |

2.91 gph |

1.38 gph |

1.86 gph |

1.13 |

On average, wood stoves spend over 80% of their life in the low to medium burn rates.

Q: How does a hybrid stove operate compared to a non-catalytic stove.

A: An easy to use bypass lever allows you to quickly heat up the chimney before engaging the burn system. In addition to hybrid stoves, many non-hybrid stoves offer this same bypass feature as an added benefit to the operator.

Q: Does a catalytic stove require more maintenance?

A: Yes: About 5 minutes per month is needed to clean ash off the catalyst. Maintenance is easier than ever in a well-designed hybrid stove. The catalytic can remain in place during any cleaning or maintenance of the stove. If needed, the all-metal catalytic can be removed in seconds with no chance of damage. The combustor can be re-installed in seconds with a new gasket.

Q: Is there restriction on what fuel I can burn?

A: No more than any other stove: All wood stoves are required to have an extensive list of prohibited fuels that include glossy paper and chemically treated materials. If you shouldn’t burn it in a hybrid stove, you shouldn’t burn it in any stove.

Q: How long will the catalytic last?

A: Omni Environmental Laboratories, an independent test lab, performed a study on the effectiveness of catalytic combustors over time. The data showed that after 9 years of use, a stove equipped with a combustor is still cleaner and more efficient than non-catalytic stoves. Additionally, the warranty on a Kuma Hybrid combustor is 12 years: That is 7 years longer than some manufacturers will warrant their entire stove.

Q: How do I know if my catalytic stops working?

A: With a hybrid stove, the thermal combustion system (burn tubes) does most of the work so you will likely not notice any reduction in performance over time.

Q: Are combustors unreliable and fragile?

A: No, an all-metal combustor encased in thick stainless steel is just as durable as any other baffle component in a stove. 40 years ago, some poorly placed ceramic combustors were prone to early failure. Some manufacturers may attempt to scare customers with this outdated misinformation.

Q: Why do manufacturers use them?

A: To achieve longer burn times and higher efficiency than non-catalytic stoves. If you compare the burn rate and efficiency from each stove’s official test data, you will find the hybrid stove to be unquestionably superior.